Temperature compensation when testing battery banks

A battery’s capacity is dependent on the ambient temperature. If the ambient temperature is high the capacity increase, but it will at the same time shorten the battery life. In the opposite direction, when ambient temperature is low, the capacity of the battery is reduced. This must be considered

when performing a capacity test.

Nominal temperature for battery specifications is normally 20ºC/68F or 25ºC/77F. In order to compare the test result from a discharge test with the battery specification, the temperature must be considered. There are international standards that describe the temperature compensation procedure, IEEE 1188 (VRLA), IEEE 450 (vented) and IEC 60896-11/21(vented/VRLA).

TORKEL 900 has implemented all these temperature compensation methods according to the standards. To enable the temperature compensation, press the  button. Select “Settings” and set to ON for temperature compensation. The

button. Select “Settings” and set to ON for temperature compensation. The button coms up were temperature can be set, and IEEE or IEC standard can be selected.

button coms up were temperature can be set, and IEEE or IEC standard can be selected.

- IEEE 450 and IEEE 1188

Tests longer than 1 hour

The most commonly used temperature compensation method in these international standards is to apply the temperature correction to the capacity calculation after completion of the test.

C = (ta / ts x Kt) x 100

Where

C is the % capacity at 25°C

ta is the actual time of test to specified terminal or cell/unit voltage

ts is the rated time to specified terminal or cell/unit voltage

Kt is the correction factor for the cell temperature before the start of the test

Simply run the test at rated current and time. When the desired voltage level has been reached the test is stopped. The temperature compensation is when performed according to the calculation above and the % Capacity is calculated.

In an earlier version of the IEEE standards there was a possibility to perform the temperature compensation prior to the test by adjusting the test time. This method is still valid and can be used.

Temperature compensation after performed discharge test.

Disable( if enabled ) the temperature compensation on the “SETTINGS” menu by clicking on the  button and disable temp compensation. Go to the “RESULT” tab and select the

button and disable temp compensation. Go to the “RESULT” tab and select the  button. Disable the temperature compensation. Set “Rated capacity” and temperature. Start the test from the “RESULT” tab. After test has been stopped, press the

button. Disable the temperature compensation. Set “Rated capacity” and temperature. Start the test from the “RESULT” tab. After test has been stopped, press the button and save the test. Enable the temperature compensation in the “RESULT” tab. This gives the “%Capacity” value.

button and save the test. Enable the temperature compensation in the “RESULT” tab. This gives the “%Capacity” value.

Temperature compensation before start of discharge test.

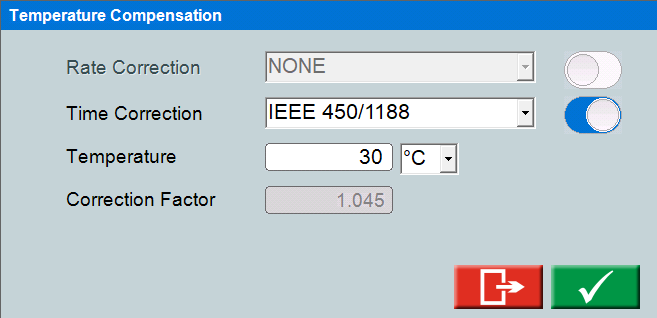

Click on the  button. Below menu comes up.

button. Below menu comes up.

Enable “Time correction”. And set temperature. When rated time is set on the start menu, compensated time is calculated for the specified temperature. The “Rated Capacity” on the “RESULT” tab shall also be set. The “%Capacity” are then calculated.

Tests shorter than 1 hour

For these tests a different method is used, current rate compensation which is made prior to the test. The discharge current for the test will then be compensated relative to the nominal rate. If the temperature is higher than 25°C, the current discharge rate is increased. If lower than 25°C, the current discharge rate is decreased.

% capacity at 25 °C = Xa x Kc / Xt x 100

where

Xa actual rate for the used test

Xt published rating for time t

t time of test to specified terminal voltage

Kc temperature correction factor